Automation of car weighing station

The main aims of car weighing process automation are to reduce the influence of human factor, eliminate misrepresentation of weighing results, increase speed of data processing and document forming.

Complex system of motor transport weighing control – is a result of accounting system, video surveillance and truck scales integration. This solution in demand at industrial enterprises, carious logistics complexes, warehouse terminals, elevators etc. Apart from control and automation, the system facilitates work of enterprise employees: operators, drivers, lab assistances and accountants. Automated truck weighing station is the whole complex of integrated systems: truck scales, video surveillance system and accounting program. If needed operator’s work also can be automated - in this case drivers can start weighing operation themselves. Driver can start weighing operation with the help of bar-code document and identification card. Moreover, the activation can be started at a signal of RFID-tags reader. Specific implementation depends on peculiarities of enterprise. The main aim is simplicity, reliability and recoupment.

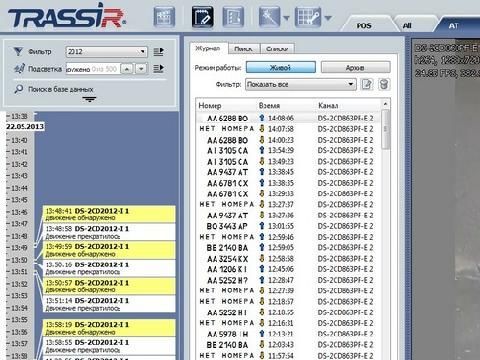

Intellect and Trassir systems are used as video surveillance ones. The choice of platform depends on the peculiarities of the project, the scales of enterprise and extension plans. Truck weighing system is designed taking into account all the peculiarities of enterprise and technological processes. For video control and events analysis, special user interface is adjusted that helps to choose and watch video tapes: weighing, bar code scanning, document forming, printing etc. registration number identification system also can be installed. It is necessary to remember that automatic recognition is not 100% reliable and used as an additional control subsystem. Economic reasonability of automated recognition is to be calculated.

Operator’s automated worksite is designed on the basis of accounting system of enterprise. Usually it is 1C: Enterprise 7.7 or 1C: Enterprise 8.2.

Practically any electronic truck scales can be used for technical implementation. Tekhnovagy scales are ones of the most reliable truck scales with adjusted data transmission protocol and excellent guarantee and service support.

Currently Tekhnovagy Company is an absolute leading scales producer. Only highly qualitative scales can be used for automation system implementation.

Project of truck weighing station automation is designed specifically for individual enterprise considering specific tasks and business-processes. Our demo-stand can help to demonstrate the principles of system operation. However, individual analysis and system designing are needed for each truck weighing station. It can be full automation with remote control from office or partial – with operator. Besides, documents processing and forming are adjusted individually with subsequent automation of documents circulation processing on the basis of bar codes.

Example

1. Entry of truck on the scales. Driver identifies himself and his truck with the help of personal cards.

2. Automated receiving of weighing results and if needed registration number of truck and trailer.

3. Initialization of document forming.

4. Filling in the document form and printing.

5. The results of weighing are saved in the accounting data base and duplicated in the video surveillance system.

6. The truck is loaded or unloaded.

7. Repeated weighing: truck entry on the scales, scanning of bar code receipt.

8. Weighing statement is formed automatically; load is weighed than statement is printed.

9. In accounting department bar code of act is scanned and than shipping documents are formed automatically.

An example of weighing statement. Such a statement is given with truck scales.

Label printer prints the following label (weighing statement). The printer is integrated into automated accounting system of truck weighing station.

Bar code in weighing statement allows automating its further processing and forming accompanying documents: consignment notes, certification of conformity, route list.