Thermal label TOP or ECO. What is the difference?

Thermal label - this label is based on special paper, consisting of several layers, which have different composition and purpose.

The first layer (outer) - thermochemical, it is intended for printing various information, when heated, this layer darkens almost instantly, which, in fact, ensures the appearance of information on the label.

The second layer - this is usually ordinary paper, and underneath this layer there is an adhesive base, thanks to which the thermal label can be glued (depending on the adhesive) to various surfaces.

And finally, the last layer is — This is a special backing, thanks to which labels can be stored in rolls without fear that they will stick together.

There are two types of thermal labels: thermal Eco and thermal Top.

Thermal Eco label. Such labels are produced from white, wood-free paper treated with a heat-sensitive coating. The production of such labels is relatively inexpensive. Information printed on such paper may fade when exposed to UV light, and the label dissolves when in contact with moisture. Such labels are used when the labeled products do not require long-term storage or transportation. Most often used for labeling fast-selling goods under standard storage conditions. Temperature range of application from +5°C to +40°C, minimum gluing temperature +5°C.

Used when further printing of information is required on thermal printer or when used in scales with label printing.

The mechanism for printing on thermal labels can be located in the scale body or on a stand with a weighing processor.

Thermal label Thermo Top. This type of label is produced using white, wood-free paper that has a 2-sided heat-sensitive, smudge-resistant, coating.

The ThermoTop label is highly resistant to water and fats, and is also more resistant to smudging, unlike the ThermoEco label. ThermoTop is used to label goods if their storage conditions are not very favorable, as well as during further transportation and long-term storage. The temperature range of application is from –40°C to +50°C, the minimum gluing temperature is +5°C.

By and large, thermal TOP differs from thermal ECO only in one additional protective layer, therefore TOP is more expensive than ECO.

Thermal label of standard sizes (40x25 mm, 58x40 mm, 58x60 mm) are always in stock. Depending on your label printer, you can order roll labels with any winding.

TOP thermal labels are more expensive than ECO, since TOP thermal labels have a protective layer and retain their quality characteristics with sudden temperature changes.

Three rolls of labels are visually identical, but different in material.

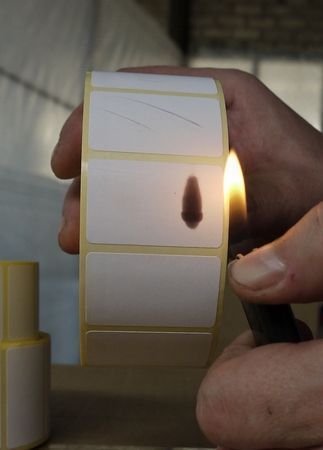

You can distinguish a thermal label from a paper one in a more than simple way: you should bring the label to the flame of a lighter. If the label darkens, then we have a thermal label in front of us.

If it does not change its color in a matter of seconds, then it is a semi-gloss paper label and you need a ribbon to print on it.

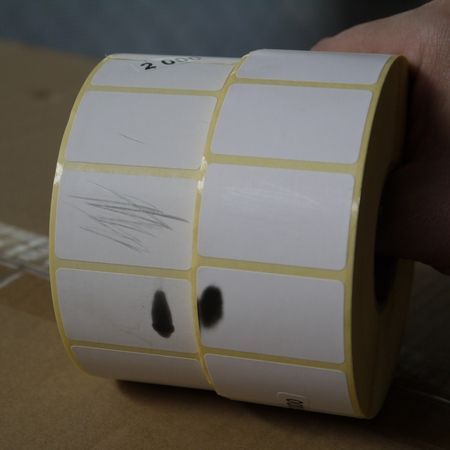

How to distinguish an Eco thermal label from a Top thermal label? The TOP label has a protective layer, thanks to which it is protected from minor mechanical damage.

Therefore, you should scratch the label with your fingernail: the ECO thermal label will leave a mark, unlike the TOP one. Read more about the quality and selection of thermal labels in the article — "Choosing a thermal label".

Here are our labels after a small experiment.

Currently, thermal labels are used as actively as paper or polypropylene labels. An ink ribbon is used to print on paper and PP labels. Such labels are printed only on a thermal transfer printer.

In addition to supplying label printers and consumables for them, we offer services for operational printing labels.