Causes of poor printing on labels

Have you bought a label printer and are you printing labels yourself? Everything seems to be fine - both the labels and the ribbon, but the printed labels are of poor quality. What's the matter? There are many reasons for poor label printing. Here are the main ones.

The label printer is not printing well

1. The print head is dirty. Dust from the labels and ribbon gets on the thermal print head and sticks to it. You can fix this problem by cleaning the print head. It needs to be cleaned with a cotton pad, which is pre-moistened with alcohol.

2. The label is of poor quality. Labels differ in the quality of the material and the adhesive layer. Choosing thermal labels for your printer should be done responsibly. Labels that look the same can be of different quality.

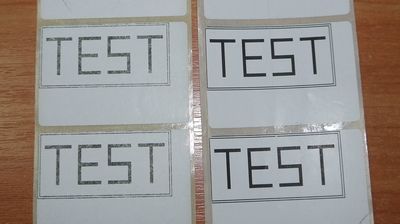

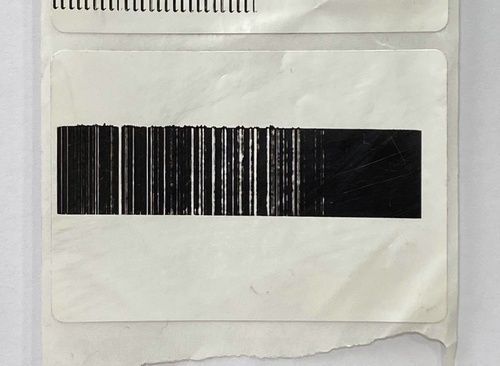

The photo shows printed thermal labels with different material quality.

Printing was done on the same printer Godex G500 and on thermal labels with the same shelf life.

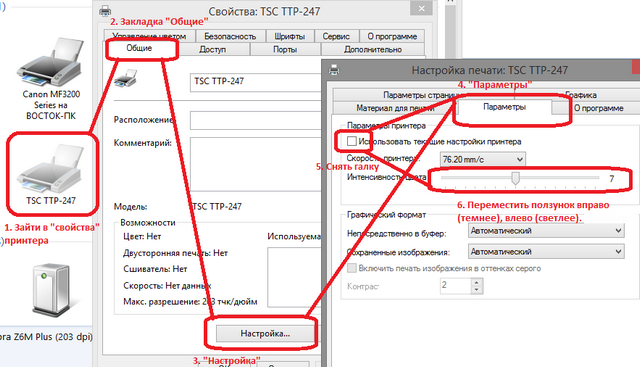

3. The print head temperature is set to low. Fuzzy and faded print may be the result of a low print head temperature setting.

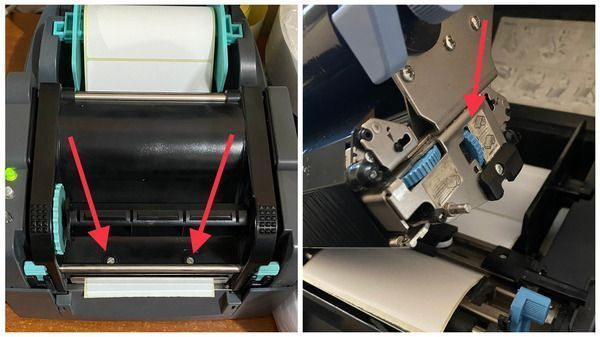

Change the thermal head temperature in the settings — and the print will be more contrasting and clear. Below is a visual guide on how to adjust the temperature of the label printer thermal head. It is important to remember that different types of ribbon and different materials of labels and tags require their own optimal thermal head temperature.

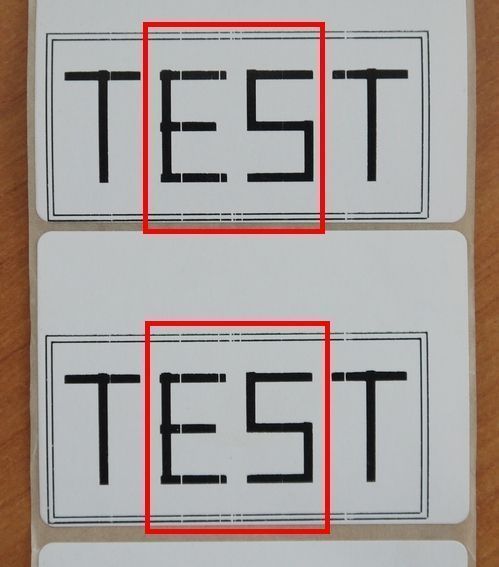

4. Damaged thermal head is one of the reasons for printing "striped" labels. This reason cannot be eliminated by adjusting the print parameters. The thermal head is a printer consumable and cannot be repaired. A damaged print head can only be replaced with a new one.

The cause of white vertical stripes when printing labels is a punctured or worn out print head.

Scratches and chips on it can lead to the printing of a damaged barcode, which is not considered a barcode scanner in the future. Print head is usually the most sensitive component of a label printer. To avoid the problems described above, it is necessary to clean the print head systematically. In half of the cases, the thermal head has to be replaced due to its improper and careless use. Cleaning the print head at regular intervals can significantly extend its service life. According to generally accepted rules, the print head must be cleaned every time the ribbon roll runs out.

5. Thermal head pressure. The print on the label is uneven from edge to edge horizontally (along the width of the label). On one edge, the print is saturated, but gradually towards the other edge it becomes paler and paler. In this case, it is necessary to adjust the thermal head pressure in accordance with the width and thickness of the printed material.

As a rule, such adjustment is in the operating instructions for the label printer. Each printer model has its own adjustment of the material thickness and the angle of the thermal head.

The above are the top five reasons for poor label printer print quality. If you have eliminated all of them, but still have questions about setting up - call 068 405 41 11 and our specialists will help you set up the printer and create a label layout.