Evolution in labeling

From typographic printing to self-adhesive label printing. Predecessors of roll self-adhesive labels.

Today there is no need to order all sorts of tags and labels from a printing house, place an order, wait for it to be manufactured and delivered. And get a thin paper label at the output.

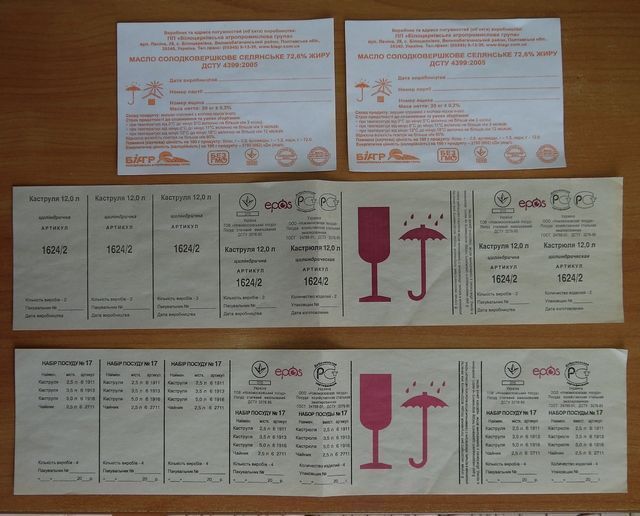

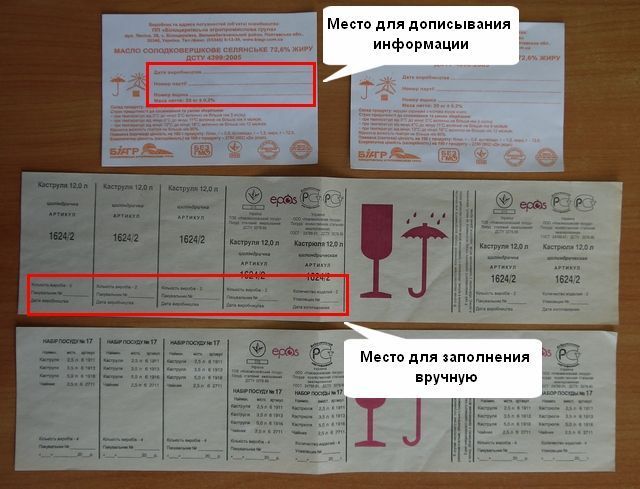

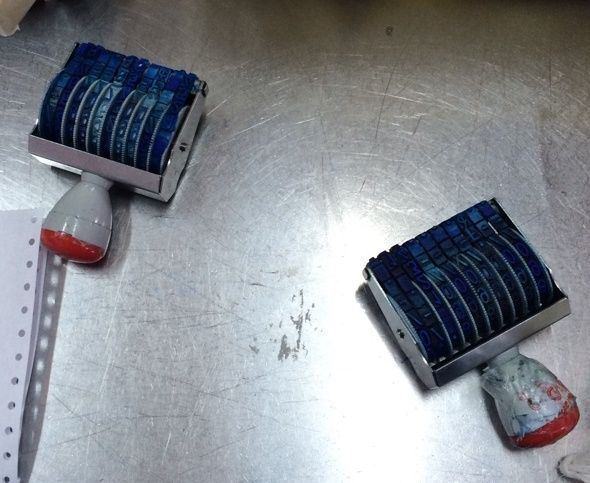

And besides, on such a label it will be necessary to add the necessary information or put it with stamps.

Here is an example of how products were marked before using a label printer.

And how much hassle with gluing paper printed leaflets?!

The problem of marking is solved very quickly and easily today — label printer and labels of the required size.

Marking with a label printer.

This method of labeling has only advantages.

The main advantages of printing labels with a printer

- Saving working time.

- Moving away from stamps and date stampers with ink.

- A wide range of label sizes.

- Self-adhesive labels. No need to spend extra time gluing paper printing glueless labels.

- Quick printing.

- Printing in small runs.

- Labels are stronger than paper sheets with information. Less susceptible to moisture and mechanical impacts.

- Labels adhere better to the box or product.

- Several material options. The label can be paper, polypropylene, thermo TOP or thermo ECO. (Thermal label TOP or ECO. What is the difference?)

- Printing a barcode on labels.

- Printing variable information (which you can't do in a printing house).

- Nothing needs to be written on the labels. The label layout and information are set from a PC.

Save your time and money with a label printer!

How to choose a label printer?

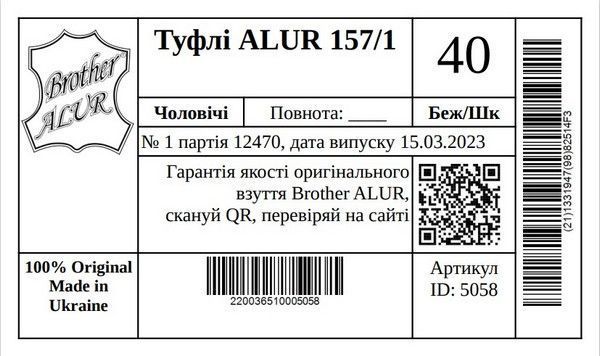

Web passport of products - as the pinnacle of labeling evolution! Adding a QR code of the link of the web passport of products takes labeling to a new high-tech level. By scanning the QR code with a smartphone and opening the web page of their product, the buyer can get full information about the product, check the originality, register the product and take part in the promotion.