RFID systems

Radio Frequency Identification systems are based on various standards and technologies. The only thing that unites these various standards and technologies is the method of transmitting information - radio frequency.

The basic elements of an RFID system are a reader, an antenna and a tag. But these are only the initial elements, in addition to them, an RFID system includes software for readers, drivers for exchanging data with the enterprise accounting system, a coding and identification scheme.

RFID technology does not require contact or direct visibility between the tag and the reader, which allows you to simultaneously read several tags that are currently within the antenna's range. RFID systems can be used even in aggressive environments, RFID tags can be protected from external influences by a radio-transparent case (tag carrier). Information exchange between the reader and the tag occurs through dirt, paint, steam, water, plastic, wood.

For identification, it is important that RFID tags are virtually impossible to counterfeit. Information stored on a radio frequency tag can be encrypted, and access to reading and/or writing can be password protected. Depending on the tag type (chip technology), one radio frequency tag can simultaneously store both publicly accessible data and restricted data.

Equipment and tags for RFID systems

When building an RFID accounting and control system, it is necessary to solve the main tasks:

1. Marking products with an RFID tag and a barcode label;

2. Monitoring the movement of products between areas of the enterprise;

3. Monitoring assembly and order formation;

4. Output control at the checkpoint.

Marking products

There may be several marking options. They depend on the business processes of a particular enterprise and its logistics chains. The main options are:

For labeling products with RFID tag and barcode label, RFID module label printers are used — RFID printers. When printing a label, information is written to the RFID tag, the label is coded with a password, and then applied to the product.

Options may vary. For example, in window production, the label is a production order and accompanies the assembly of the product, from planning to release. In other cases, when the product is not tied to an order, but is produced in series, labels are printed for the entire batch and then applied, still impersonal, to the products in the finished goods warehouse.

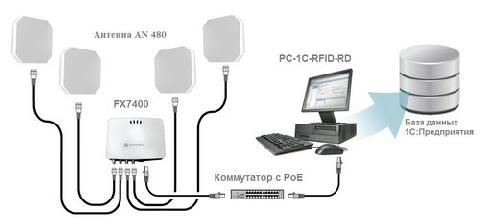

Control and accounting of products at stationary posts

Accounting and control points are equipped with stationary antennas and stationary RFID controllers. Depending on specific tasks, it is possible to control the crossing of a product of a control point, the direction of movement of a product, the presence of a product with a tag in the control zone. To control production from raw materials and semi-finished products to finished products, it is effective to use containers marked with RFID tags: boxes, containers, carts, frames, pallets. Each accounting unit of packaging is a temporary storage location, which allows tracking the movement of products between production areas virtually online.

The results of reading the tags are recorded in the database, which allows for prompt tracking of the movement of packaging and products. The RFID system can be integrated with other enterprise accounting systems, with operational or management accounting, WMS warehouse management systems, and a system for managing movement across the enterprise territory.

RFID enterprise asset management system

Using mobile and stationary RFID tag readers, it is possible to organize effective enterprise asset management systems.