Weighing and marking

Vostok company employees design complex budget solutions for products weighing and marking at industrial and production enterprises.

Standard equipment and software are used in solutions that allows adjusting the scheme of work if needed.

The advantages of weighing and marking complex:

- Using of any accuracy and MLW scales – from jewelry scales to automobile scales.

- Using of budget label printers for small printing volumes, as well as industrial printers of high capacity.

- Using of paper, polypropylene labels.

- Printing of information with resolution more than 200 dpi.

- Printing of 1D and 2D bar codes and other information on large labels in large volume.

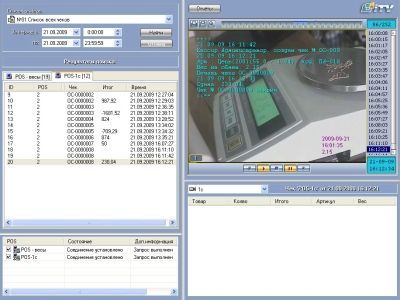

- Video control – transmitting of information: weight, product type, container number, information about employees etc, to video surveillance system for extra analysis and control.

- Various algorithms of operation and check up.

The disadvantages are the following – prolonged time of system adjustment in comparison to the installation and programming of label printing scales.

As a rule, weighing marking complexes are integrated into unique complex with accounting program mostly with 1C: Enterprise. The solution is flexible and multipurpose. Practically any scales and label printers can be connected to the system. Moreover, operational accounting and control of operations are ensured.

Label printing scales are also can be used for weighing and marking. However, label printing scales do not have all the advantages as the complete weighing and marking complex may have. MLW of label printing scales is 30 kg while weighing and marking complex may include scales with any MLW.

Label printing scales will help to determine weight and automatically calculate the cost of product, embedded printer will print the results of weighing on self-adhesive thermal label for products marking. More detailed information you can read article about Label printing scales.