Meat processing plant weight accounting

Weight accounting of raw materials, semi-finished products and products is used at all stages of production of meat and sausage products. It is necessary to ensure end-to-end operational accounting and control along the entire production and logistics chain of the enterprise - from the acceptance of raw materials to the sale of finished products.

One of the important conditions when choosing scales for meat processing plants and sausage shops is the presence of an interface for connection to a PC or computer network. This option has virtually no effect on the cost of the scales, while the presence of an interface allows you to automate accounting at a meat processing plant at any time - either completely or in stages.

The meat processing plant uses the full cycle of meat processing from slaughter to finished meat and sausage products. Meat processing plants purchase live scales and accept through scales for weighing livestock. At the first stage of accounting automation, electronic scales equipped with an interface for connection to a computer are usually used, but at the same time, the scales operate autonomously and are not connected to the enterprise's computer network.

It is advantageous to use scales for group weighing animals

The sausage shop purchases half carcasses, acceptance and weighing of raw materials is carried out through monorail scales, platform or commodity scales.

Carcass and half-carcass marking is necessary for operational accounting. Marking can be done using labels, tags, stickers.

Meat cooling and storage requires weight control - this is necessary both for monitoring natural loss within the norm, and to prevent theft. Defrosting - depending on the accounting scheme of the enterprise, it is necessary to periodically or constantly weigh the raw materials on monorail scales before and after the defrosting process.

The production of meat and sausage products includes several operations

- Slaughterhouse - a section of the enterprise or a separate enterprise where cattle are slaughtered and primary processing of carcasses is carried out.

- Boning - cutting up animal carcasses, separating meat from bones.

- Tennising - separating meat by grade (pork: fatty, lean, semi-fat; beef: premium grade, first grade, second grade).

- Minced meat preparation - production of minced meat by mixing components and grinding them in sausage cutters.

- Forming — filling sausage casings with minced meat on sausage stuffers and sealing the ends of the casing on clippers.

- Drowning — keeping sausage sticks with minced meat at a low temperature before heat treatment in accordance with the production technology of a particular sausage.

- Heat treatment — the processes of drying, frying, cooking and smoking sausages in sausage thermal chambers, the process of showering (cooling sausages with water and air).

Weight accounting along the production chain of meat and sausage production is carried out at many stages.

Slaughterhouse — slaughter of cattle and primary processing of carcasses, scales for cattle, single weighing (scales for cattle and small cattle TV4-1000-0,2) or group weighing are used. The slaughterhouse is also equipped with monorail scales for weighing half carcasses, platform and commodity scales for weighing skins and waste. Technological accounting after cooling - can be used continuously or periodically as control measurements to establish

standards of permissible deviations and losses.

Boning — cutting up animal carcasses, separating meat from bones — monorail scales are used to accept carcasses (half carcasses), products are weighed on commercial scales in plastic boxes. For better ergonomics and protection of scales from impacts, they should be placed on pedestals.

Tennis cutting — separation of meat by grade — weight accounting is carried out using commodity scales, products are sorted into plastic boxes.

Minced meat preparation — production of minced meat by mixing components and grinding them in sausage cutters.

Molding — filling sausage casings with minced meat in sausage syringes and sealing the ends of the casing in clippers — After forming, the products are placed on a trolley and weighed on a platform scale. To facilitate the accounting of the tare weight, the trolleys can be marked with a tare bar code.

Sedimentation - keeping the product at a low temperature before heat treatment in accordance with the production technology of a particular sausage - before and after the settling, the cart with the products is weighed on a platform scale.

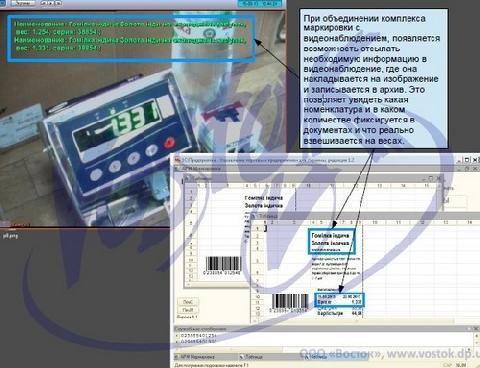

The weighing of the cart is registered in the accounting program, the cart number is entered, the system automatically calculates the weight of the products and prints an accompanying label with bar codes.

Heat treatment is the same weighing process as before settling — products on the cart are weighed using platform scales.

Warehouses for storing finished products — receive finished products from production, control their quantity, weight and quality. The weight of the products is checked using platform and commodity scales.

Filling, packaging and labeling of products — for weighing, packaging and labeling of meat and sausage products, check-printing scales, checkweighers, as well as weighing and labeling complexes based on electronic scales and label printers are used.

Shipment of products (expedition) — products are shipped via platform scales or rokla scales.

For weighing elite and expensive sausage products shipped in small quantities, it is necessary to use packaging or commercial scales.

If you are interested in the accounting system at the meat processing plant - send your request and questions to the e-mail address vostok@pkf.dp.ua, via the feedback form or call (056) 720-90-37; (067) 384-69-83. We will make preliminary calculations and make a commercial offer for you.